School-bus breakdowns are inconvenient, costly, and potentially dangerous. Summer is the ideal time to complete vital maintenance and confirm that every vehicle meets state and federal requirements. A structured checklist—and accurate digital maintenance records—helps technicians work methodically while supporting compliance audits.

What Is a School Bus Summer Maintenance Checklist?

School-bus maintenance is not just good practice; it is required by several regulatory bodies. Under the Federal Motor Carrier Safety Regulations, § 396.17, every commercial vehicle must undergo a comprehensive inspection at least once every 12 months. Robust summer checklists also:

- Verify DOT compliance documentation

- Confirm preventive-maintenance items (fluids, belts, brakes, tires)

- Address FMCSA regulations

- Flag recommended repairs discovered during the school year

- Integrate software or telematics updates

- Review retirement timelines for ageing vehicles

Safety note: Fewer than 1 percent of all traffic-fatality cases involve children on dedicated school buses. (Source: NHTSA)

Always check district-level policies, as local authorities may impose additional inspection forms or reporting deadlines.

Why Summer Bus Maintenance Matters More Than Ever in 2025

Many fleets are ageing: the average U.S. school bus is about nine years old—yet most can serve 15–16 years with proper care. (Source: Wikipedia) With roughly 490,000 yellow buses transporting students nationwide, reliable maintenance underpins the entire system. (Source: NHTSA)

Tight transportation budgets make proactive repairs the best long-term investment. Schedule summer maintenance to:

- Improve safety – Regular servicing prevents faults that could endanger children.

- Capture cost savings – Prevention is cheaper than emergency repairs or replacement vehicles.

- Prevent breakdowns – Reliability protects district reputation and parent trust.

- Reduce service interruptions – Address issues while school is out to keep routes running smoothly.

- Integrate new technology – Planned downtime is ideal for installing GPS, telematics, or digital maintenance platforms.

- Increase vehicle lifespan – Consistent upkeep helps buses reach their full service life, easing budget pressure. (Source: FMCSA)

The Complete Summer School Bus Maintenance Framework: Six Essential Steps

Using maintenance time wisely in summer can reduce breakdowns, control costs, and keep your fleet compliant all year.

Step 1: Engine & Powertrain Systems Check

- Diesel-engine service: oil change, filter replacement, coolant flush

- Transmission inspection: fluid exchange where necessary

- Fuel-system cleaning and water-separator maintenance

- Exhaust-system compliance checks and emissions inspection

Step 2: Brake-System Comprehensive Inspection

- Air-brake system testing

- Pad/shoe-thickness measurement and replacement if needed

- Brake-fluid inspection and replacement of contaminated fluid

- Emergency-brake testing

- Verification of DOT and FMCSA requirements

Step 3: HVAC System Preparation & Testing

Keep your fleet ready for year-round trips with robust HVAC maintenance during the summer:

- A/C refrigerant levels and leak detection

- Heating-system functionality for winter readiness

- Regular cabin-air-filter replacement

- Ventilation-system cleaning and sanitisation

- Temperature-control calibration

Step 4: Tire and Wheel Assembly Maintenance

The value of good tire maintenance can never be overstated, as tires are the only part of the vehicle that contacts the road. Summer checks should include:

- Tire tread-depth measurement and replacement where necessary — U.S. regulations require at least 4/32 inch on steer-axle tires (49 CFR § 393.75)

- Inspection for tire damage, dry-rot, and other irregularities

- Wheel alignment and balancing

- Tire-pressure optimisation for safety and maximum fuel efficiency (NHTSA tire-safety guidance)

- Seasonal-tire rotation before winter where applicable

- Wheel-bolt inspection and tightening

Step 5: Safety Systems and Equipment Verification

School-bus safety checks not only protect students but also fulfil critical regulatory requirements. Before the new school year begins, inspect and record:

- Stop-arm and warning-light functionality (FMVSS 571.131)

- Seat-belt and restraint-system effectiveness

- Headlight and brake-light operation

- Emergency-exit testing and lubrication (FMVSS 571.217)

- Fire-extinguisher testing and first-aid-kit inspection (NHTSA school bus safety equipment)

- Student-safety mirrors and other driver-assistance features

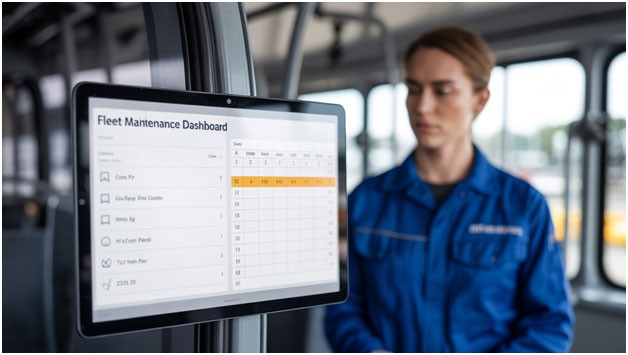

Step 6: Digital Documentation and Record Keeping

Digital records keep maintenance organised and make compliance quick and painless. During summer servicing, be sure to update:

- Digital maintenance logs that trigger automatic reminders (required retention detailed in 49 CFR § 396.3)

- Compliance documentation for state and federal regulators

- Fleet-management-software integrations and upgrades

- Real-time cost tracking and budget planning as repairs are completed

Critical Summer Maintenance Mistakes (And How to Avoid Them)

Summer maintenance is an opportunity to protect your school-bus fleet and prevent costly errors that can strain your transportation budget. Skipping steps or taking shortcuts can lead to serious problems. Here are seven critical maintenance mistakes—and how to avoid them this summer:

- Skipping minor repairs: When small issues appear during summer maintenance, they can quickly become major failures if ignored. Address minor repairs as soon as they arise to maintain safety and reduce downtime once the school year begins.

- Inconsistent documentation: Haphazard record-keeping is unnecessary in the digital era. Use standardised electronic tracking systems for all maintenance to ensure consistent and accurate records.

- Ignoring manufacturer schedules: Every vehicle is unique and comes with a manual for a reason. Follow OEM maintenance intervals; generic guidelines can lead to mechanical failures and a reduced vehicle lifespan.

- Inadequate staff training: School-bus maintenance and regulatory compliance require specialised skills. Invest in certified technician training, so staff are qualified to implement safety protocols.

- Postponing repairs: Budgeting in advance for major repairs keeps costs lower over time. Delays increase the likelihood of more serious issues that raise total expenditures overall.

- Missing regulatory updates: Requirements can change quickly. Stay current by subscribing to FMCSA email updates.

- Lack of backup planning: No matter how good your maintenance schedule is, unexpected issues will arise during the school year. Use the summer to create contingency plans that keep service running during unplanned breakdowns.

Expert Insights: How Technology Transforms Fleet Maintenance

Modern fleet-management[1] platforms integrate routing, GPS, and maintenance modules, replacing paper files and simplifying compliance. A unified system can:

- Keep regular maintenance records

- Provide reminders for upcoming service

- Offer fast access to compliance data and reports

- Track maintenance costs and budgets

- Forecast component lifespans to aid long-term planning

Frequently Asked Questions About Summer Bus Maintenance

How often should school buses receive comprehensive maintenance?

At a minimum, complete the annual inspection required under 49 CFR § 396.17 and follow each manufacturer’s mileage-based intervals.

Can districts perform maintenance in-house instead of outsourcing?

Yes—if local regulations allow and certified staff are available. Otherwise, contract a qualified service provider.

How can districts track maintenance costs effectively?

Digital fleet-management tools provide real-time cost tracking, budget forecasting, and compliance documentation.

When should buses be replaced?

Well-maintained buses can remain in service for 15–16 years; consider retirement when repair costs approach replacement value. (Source: FTA)

Your Fleet’s Summer Success Starts with Smart Maintenance

Preparation saves time, money, and administrative stress. Begin the season with a robust maintenance plan, trained technicians, and up-to-date digital records. Many districts now rely on integrated fleet-maintenance software to automate reminders and consolidate compliance data. Proactive maintenance today means fewer breakdowns—and safer rides—throughout the school year.